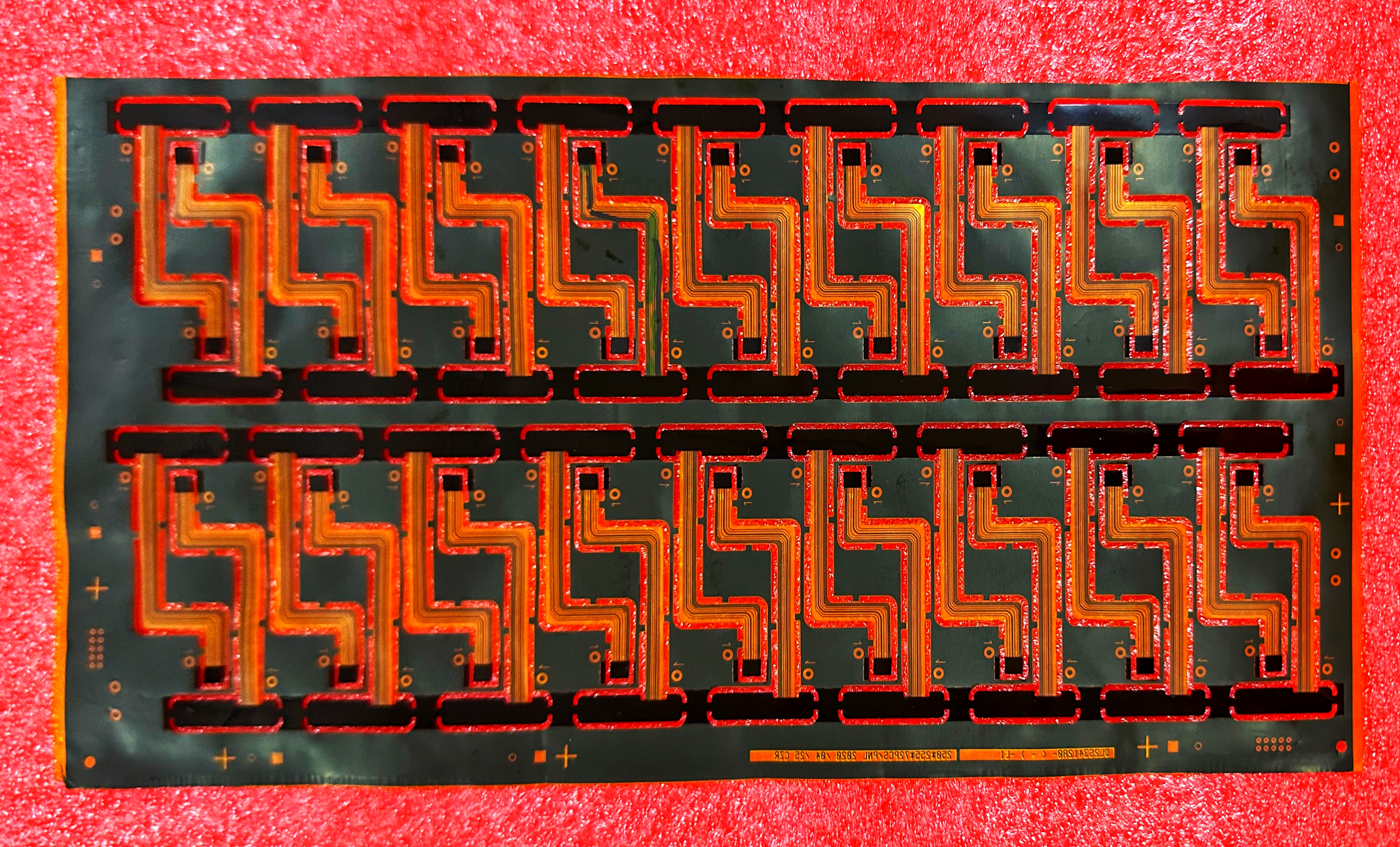

Nā huahana

6ʻO ka pnb flexible flexible

Huahana kikoʻipiop

| Nā papa | 6 flex flex |

| Ma ka papa o ka papa | 0.2mm |

| Waiwai | Polymide |

| Kaiaulu | 0,5 / 0.5 / 0.5 / 0.5 / 0.5 / 0.5 / 0.5oz (18/18/18/18/18 / 18/ 18 |

| Paulapua | Enig au mānoanoa 1um; Ni Trintness 3M |

| Minle (mm) | 0.23mm |

| Min Line Lulu (mm) | 0.15mm |

| Min laina (mm) | 0.15mm |

| Kūʻai lilo masha | Melemele |

| Kala kala | Keʻokeʻo |

| Ke kaʻina hana | V-Scoring, CNC MILIING (ROUTING) |

| Paliole | 'Oluʻa Anti-Static Bag |

| E-ho'āʻo | Flying Probe or Filesure |

| ʻAeʻia | IPC-A-600h Class 2 |

| Noi | Kaʻaahi kalaiwa |

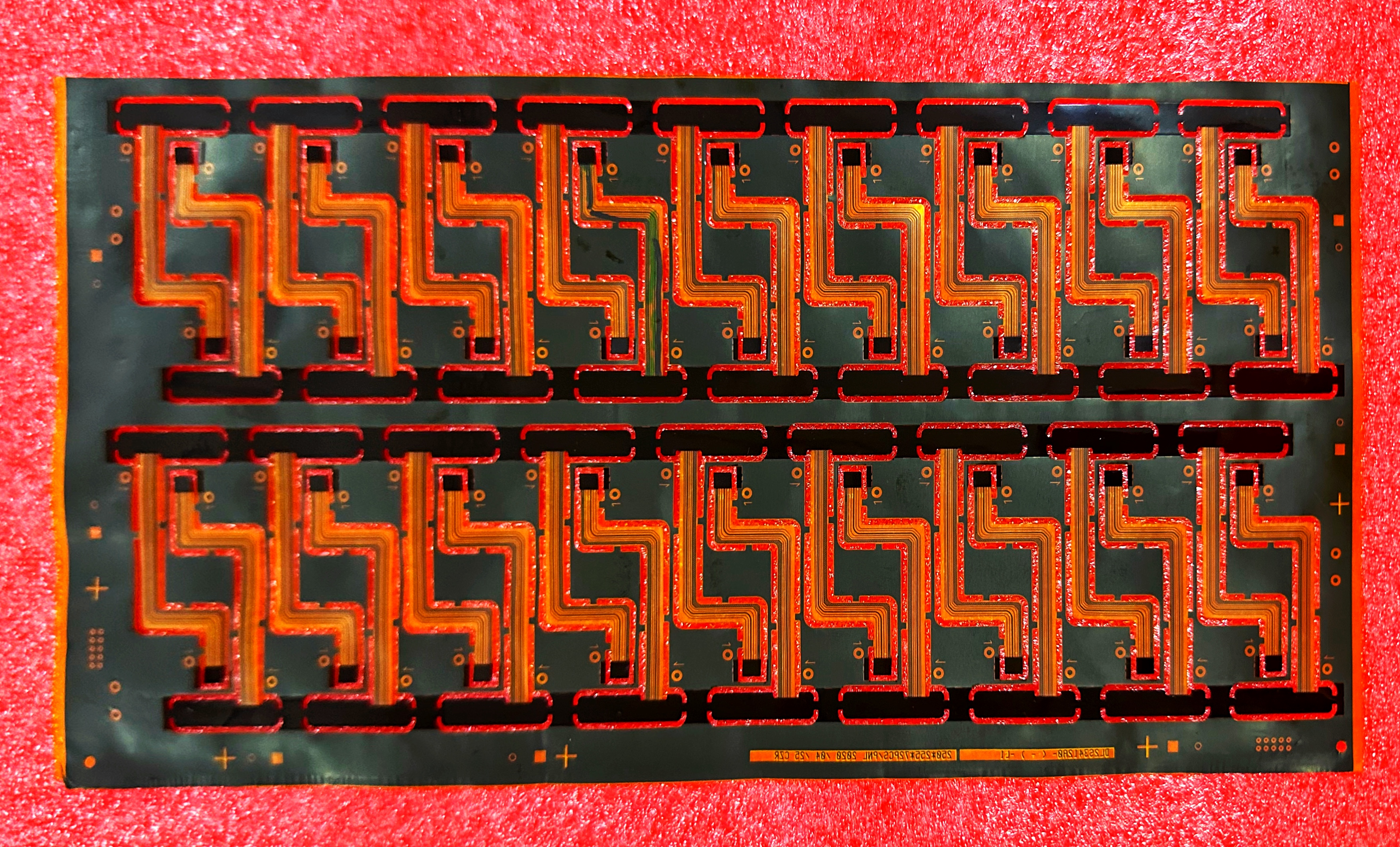

Hōʻikeʻike

ʻO kahi flex PCB kahiʻano kūʻokoʻa o PCB i hiki iāʻoe ke kūlou i loko o keʻano makemake. Hoʻohana pinepineʻia lākou no nā hana kiʻekiʻe a me nā hana kiʻekiʻe kiʻekiʻe.

Ma muli o kona pale wela wela, kūpono ka hoʻolālā flexxble no nā mea kūʻai aku i nā mea kūʻai aku. ʻO ke kiʻi Polyesp Hoʻokaʻa i hoʻohanaʻia ma ke kūkuluʻana i nā hoʻolālā Flex e lawelaweʻia e like me ka mea i hoʻopukaʻia.

Hiki iāʻoe ke hoʻoponopono i ka mākeke keleawe mai ka 0.0001 "i loko o kahi o ka meaʻaiʻo CIVELETRIC ma waena o 0.0005". He liʻiliʻi liʻiliʻi i nā interconnect i kahi hoʻolālā hoʻolālā.

No laila, he liʻiliʻi nā pilina kālā. Eia kekahi, laweʻia kēia mau huapalapala i 10% o ka papa papa'āina

ma muli o kā lākou uku wikiwiki.

Waiwai

Hoʻohanaʻia nā mea a me nā mea e pono ai e hana i nā hana flexcible. Hiki i kona hoʻololi ke hoʻololiʻia e huliʻia a neʻeʻoleʻole i hōʻehaʻole i kona mau'āpana a iʻole nā pilina.

ʻO nā'āpana āpau o kahi flex PCB e hana pū me ka maikaʻi. Ponoʻoe i nā lako likeʻole e hōʻuluʻulu i kahi papa flex.

Uhi uhi luna

ʻO ka mea lawe kaʻa a me ka hoʻopiliʻana i keʻano medium e hoʻoholo i ka hana o ka substrate a me ka kiʻiʻoniʻoni. Eia kekahi, hiki i ka substrate ke hiki ke hoʻopaʻaʻia a curl.

Hoʻohana pinepineʻia nā pepa polyinede a me nā'āpana polyester i loko o nā circila uila. He mau liʻiliʻi kēia o nā kiʻi polymer he nui e loaʻa ai, akā he nui nā mea e koho ai mai.

He koho maikaʻi loa ia ma muli o ke kumukūʻai haʻahaʻa a me ke kiʻekiʻe kiʻekiʻe.

ʻO ka pikolimide maʻamau ka mea maʻamau i hoʻohanaʻia e nā mea hana. Hiki i kēiaʻano o ka resin rein i hiki ke pale i nā mahana kiʻekiʻe. No lailaʻaʻole pilikia ka melting. Ma hope o ka polommerization thermal, ke hoʻomau neiʻo ia i kona elasticity a me ka wikiwiki. Ma kahi o kēia, he waiwai maikaʻi nā mea uila.

Nā mea hana

Ponoʻoe e koho i ka mea hana e pili ana i ka mana transfers e pono loa. Kokoke i nā carcuits explosion āpau e hoʻohana i ke keleawe ma keʻano he kumu mua.

Ma waho aʻe o kahi mea hana maikaʻi loa, he mea maʻalahi ke keleawe e loaʻa ai. Ua hoʻohālikelikeʻia i ke kumukūʻai o kekahi mea kūʻai, nā keleawe he bortika. ʻAʻole lawa keʻano o ka laweʻana i ka wela loa; Pono nō hoʻi e lilo i mea hoʻokae maikaʻiʻole. Hiki ke hanaʻia nā circictits circautits i ka hoʻohanaʻana i nā mea e hōʻemi ai i ka wela a lākou e hana ai.

Nā hashes

Aia kahi mea i waena o ka pepa polyimide a me ke keleawe ma kahi papa claccit flex. ʻO Epoxy lāuaʻo Acrylic kaʻelua mau kiʻi nuiʻelua e hiki iāʻoe ke hoʻohana.

Pono nā hāmeʻa ikaika e hoʻopaʻa i nā kiʻekiʻe kiʻekiʻe i hanaʻia e ke keleawe.