Nā lako hana PCB

Hāʻawiʻo Anke PCB i kahi koho nui o nā pono SMT me ka manuahi a me nā mīkini kikowaena kikowaena a me ka haʻahaʻa a me ka haʻahaʻa

Ma ka pcb pcb mākou i maopopo ai i keʻano o ka maikaʻi o ka hui pcb a hiki ke hoʻokō i ka hana o ka moku'āinaʻo ka moku'āina.

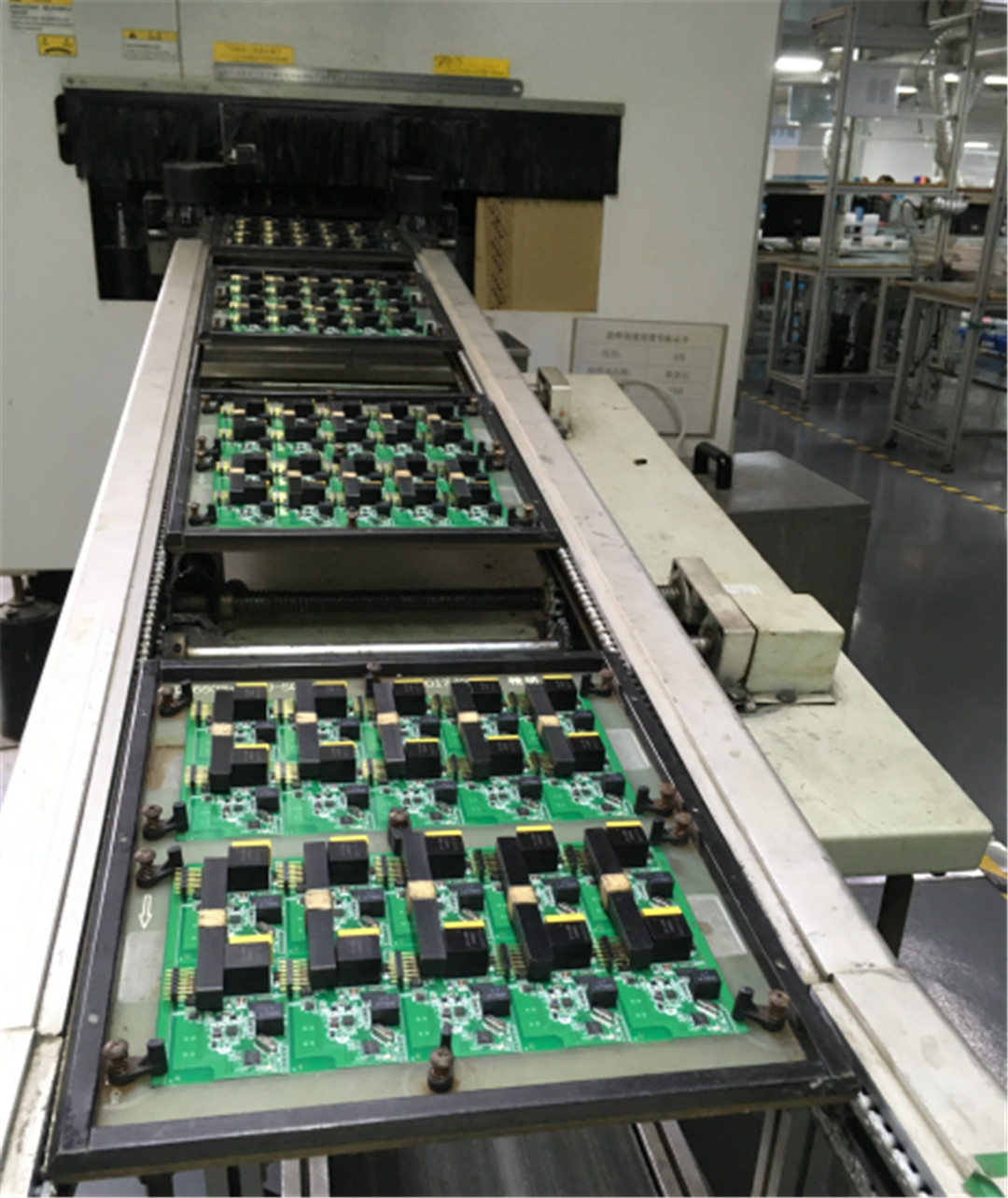

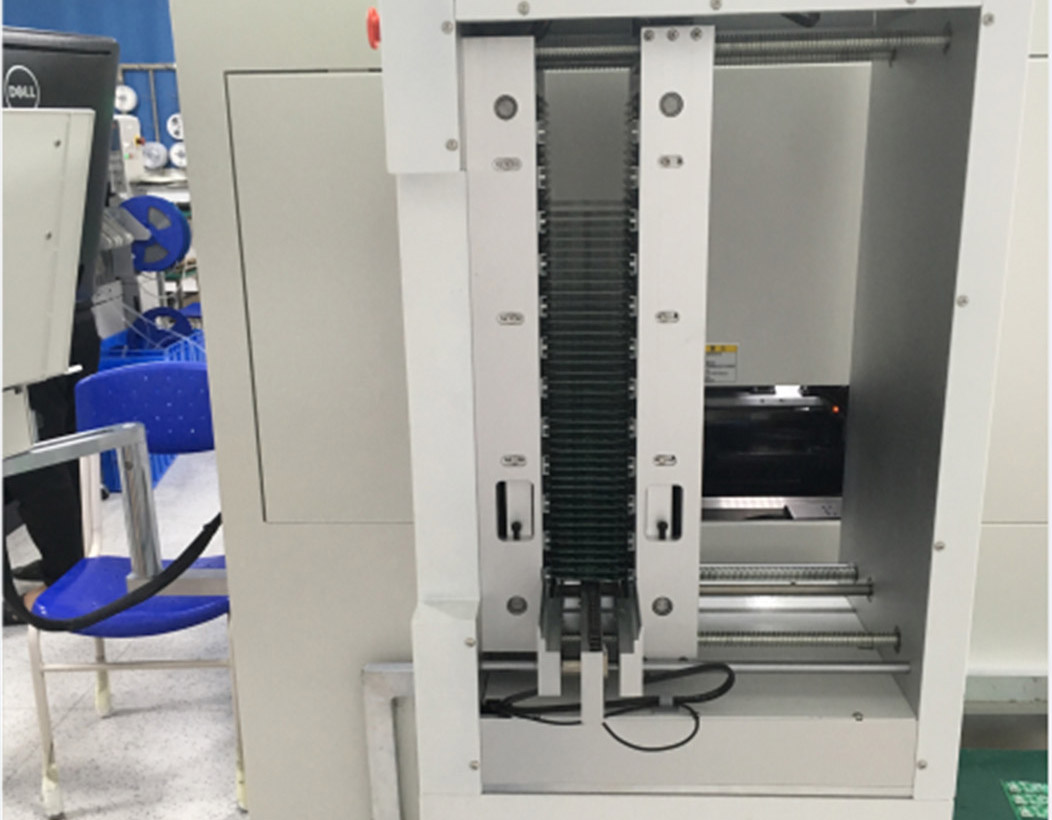

ʻO ka mea lawe kiʻi pcb print

Hāʻawi kēia mīkini i nā papa PCB e hānai ai i loko o ka mīkini kīwaha i paʻiʻia.

Pono

• Ke mālama nei i ka hana no ka hana hana

• Ke mālama nei i ka mālamaʻana ma ka hana o ka hui

• ka hoʻohaʻahaʻa i ka hewa hiki ke kumu e laweʻia e ka manual

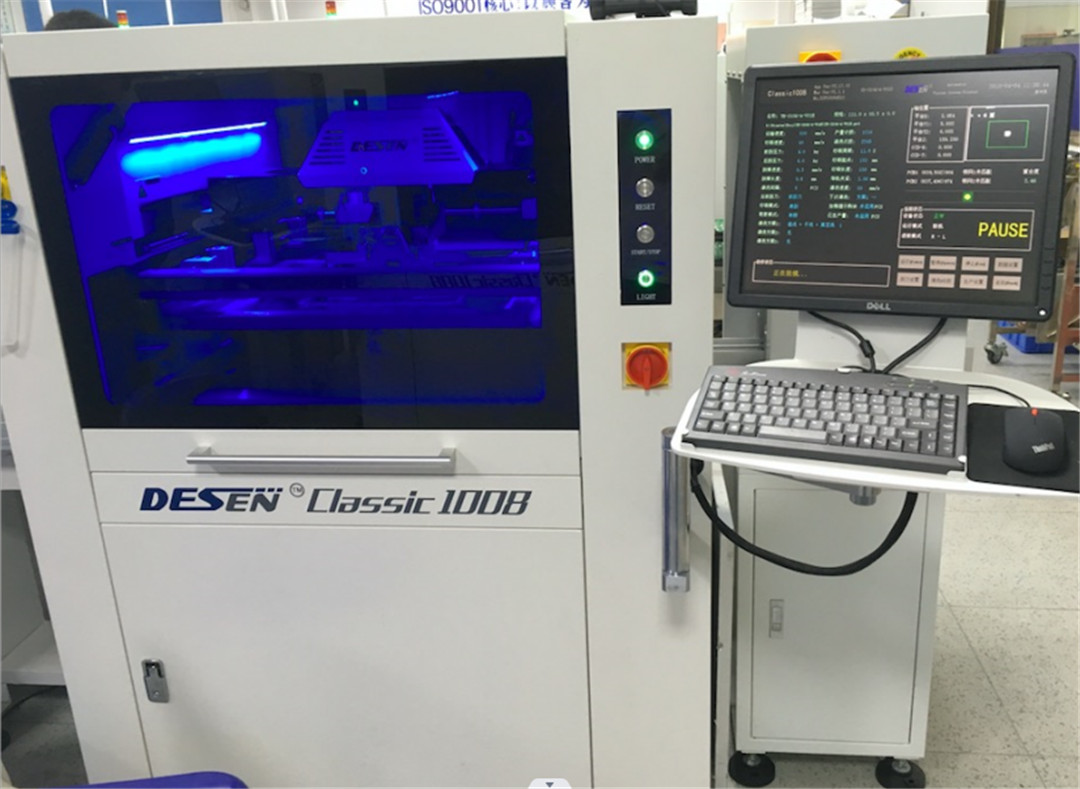

ʻO ka mīkini paʻi Stencil

He hana holomuaʻo Ake e like me nā mīkini paʻi paʻi Stencil.

• nā mea hoʻolālā

• Kākoʻo Squieegede

•ʻO ka'ōnaehana kūlana Senvil a maʻalahi

• nā'ōnaehana hoʻomaʻemaʻe kūʻokoʻa

• ka hoʻoiliʻana o ka PCB a me ke kūlana kūlana

• E hoʻohana maʻalahi i ka hoʻohanaʻana i ka'ōlelo Pelekania i ka'ōlelo Pelekania / Kina

• Kākau hoʻoiliʻike kiʻi kiʻi

• Noi Kike & H "C

• Uaʻaeʻo CCD Stencilment

Hōʻikeʻo SMT a me nā mīkini

•ʻO ka pololei kiʻekiʻe a me ke kiʻekiʻe kiʻekiʻe no 01005, 0201, SocC, BGG, BBGA, CSP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, UL, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, E CSP, QFP, UP, QFP, QFP, QFP, QFP, QFP, QFP, QFP, UP, QFP, E CSP, QFP, E CSP, QFP, UP, QFP, EXP, UK

•ʻO ka hoʻonohonohoʻana o ka laina laina laina non-post

• Hāʻawi ka'ōnaehanaʻoihana mea kūʻai aku i ka mea e nānā ai i ka hanaʻana i ka mea e nānā ai, helu helu helu helu, helu helu helu

•ʻO ka'ōnaehana hoʻohui Cgnex Algnex "ʻike ma ka lele"

•ʻO ka'ōnaehana haʻahaʻa haʻahaʻa haʻahaʻa no ka maikaʻi o ka pitch qfp & bga

• Kūpono no ka hana liʻiliʻi & medium Volume

• Kūkuluʻia-ma ka'ōnaehana kāmera me nā mea akamaiʻo Auto Smart Fucial Mark aʻo

• ka'ōnaehana dispenser

•ʻikeʻikeʻike ma mua a ma hope o ka hanaʻana

• honua codertional cad

• Kahi helu: 10,500 CPH (IPC 9850)

• Nā'ōnaehana pōkole pōkole i loko o X- a me Y-Axes

• kūpono no ka 160 mau mea hoʻokūkū hoʻokūkū hoʻokūkū

Ke alakaʻi nei i nā mea hana manuahi-manuahi

•ʻO nā polokalamu hana XP XP hana me ka China a me nā koho Pelekane. Ka'ōnaehana holoʻokoʻa ma lalo

Hiki i ka hoʻokele hoʻohui ke hoʻohālikelike a hōʻike i ka hāʻuleʻole. Hiki ke mālama pihaʻia nāʻikepili āpau āpau a loiloiʻia.

• nā PC & Siemens plc controlling und me ka hana paʻa; Hiki i keʻano kiʻekiʻe o ka hoʻoponoponoʻana i ka hoʻoponoponoʻana i nā huahana huahana i loaʻa i ka holoʻana o ka mea pili i ke kamepiula.

•ʻO ka hoʻolālāʻokoʻa o ka hale o ke aniani o nā'āpanaʻo Hapawai mai nāʻaoʻao o Hapawai mai ka nui o ka nui o ka nui o ka nui; keʻano kiʻekiʻe ma waena o 2 mau'āpana hui i hiki ke pale i ka hoʻopili ma waena; Hiki iā ia ke hoʻokaʻawale i kaʻokoʻa ma waena o nā'āpana nui a me nā'āpana liʻiliʻi a me nā'āpana liʻiliʻi a e hālāwai me ke koiʻana i ke koiʻana o ka pcb paʻakikī.

• Hoʻonui i ka ea wela a iʻole ka wai e hōʻoluʻolu ai i ka wikiwiki o ka wikiwiki me ka wikiwiki o ka wikiwiki e pili ana i nāʻano likeʻole o ke alakaʻiʻana i nāʻano mea kūʻai aku.

• ka hoʻohaʻahaʻa haʻahaʻa haʻahaʻa (8-10 KWH / Hour) e mālama i ke kumukūʻai hana.

Aoi (Otomated Inspection Inspection OPTICAL)

ʻO Aoi kahi mea eʻike ai i nā hemahema maʻamau i ka hana ulding e pili ana i nā loina optical optical. ʻO AOL kahiʻenehana ho'āʻo e puka mai nei, akā ke ulu neiʻo ia, a he nui nā mea hana a nā mea hana e hōʻike ai.

I ka wā nānāʻana, e hoʻohālikelike ana ka mīkini ma ka pcba ma o ke kāmera, a hoʻohālikelike i nā kiʻi iʻikeʻia me nā kīsilitia mea iʻikeʻia ma ka waihona. Hoʻoponopono hoʻoponopono hoʻoponopono.

ʻO ka wikiwiki kiʻekiʻe,ʻoi aku ka hoʻohanaʻana i kaʻenehana loiloi kiʻekiʻe

Nā papa hana o PC mai nā papa kiʻekiʻe kiʻekiʻe-kiʻekiʻe-kiʻekiʻe i nā papa haʻahaʻa haʻahaʻa nui, e hāʻawi ana i nā hopena kūpono e hoʻomaikaʻi i ka hana hana.

Ma ka hoʻohanaʻana iā AOL ma keʻano he mea hoʻemi haʻahaʻa, hiki ke loaʻa i nā hewa i hiki ke hoʻopauʻia a hoʻopauʻia i keʻano o ke kaʻina hana. ʻO kaʻike muaʻana i nā hemahema e pale ai i nā papa hana maikaʻiʻole e hoʻounaʻia i nā pae a pau. E hōʻemiʻo AI e hōʻemi i nā kumukūʻai hoʻoponopono a pale aku i ka paleʻana i nā papa ma mua o ka hoʻoponoponoʻana.

3D X-Ray

Me ka hana wikiwikiʻana o kaʻenehana uila

No laila, he mau uku keu kiʻekiʻe e kauʻia ma nā ala iʻikeʻia a me nāʻenehana.

I mea e hoʻokō ai i kēia koi, e kū mau nei nāʻenehana noiʻi hou hou, a me 3D maʻalahi X-ray defpection

ʻAʻole hiki keʻike waleʻia nā mea kūʻai akuʻole iʻikeʻia, e like me BGA (Burn Grid Array Price

I kēia manawa, ua hoʻopiliʻia nāʻano o nāʻenehana ho'āʻo e pili ana i ke kahua o ka hoʻokeleʻana o ka hui uila.

ʻO nā mea maʻamau maʻamau ka nānāʻana o kaʻikeʻana (MVI)

Ke nānāʻana (ka nānāʻana i ka nānāʻana. AI), ATTOTAIL X-ROY TRAPEPORCIAN (AXI), hana Tester (FT) etc.

ʻO ka Hale Hōʻikeʻikeʻo PCBA

I kahi mamao e like me ke kaʻina hana hou o keʻano o ka hui SMU a pau, e hiki ke hoʻokaʻawaleʻia i kekahi mau hana e like me ka mea e hoʻomaʻemaʻeʻia, nā hana hoʻomaʻemaʻe, a me ka hoʻomaʻemaʻe.

1 ʻO ka'ōlelo kumu nui loaʻaʻole ia e hōʻino a hōʻino paha i nā mea i laweʻia iā lākou iho, e hoʻopuni ana i nā'āpana a me nā papa hana PC.

2.ʻO ka hoʻohālikelikeʻana: Ma hope o nā mea i hoʻopiliʻia, inā makemakeʻoe e hoʻomau i nā'āpana i laweʻia mai.

3. E hoʻomaʻemaʻeʻo PCB:ʻO ka hoʻomaʻemaʻeʻanaʻo PCB CLED CLEAR e hoʻomaʻemaʻe i ka hoʻomaʻemaʻeʻana a me ka hana hana. ʻO ka papa kuhikuhi i ka papa maʻamau e pili ana i ka pae o ka papa o ka PCB o kaʻaoʻao o ka mea i koe. ʻO ka pale hoʻomaʻemaʻe hoʻomaʻemaʻe maʻamau i nā mea kūʻai aku. He mea hoʻomaʻemaʻe hoʻomaʻemaʻe, e like me ke koa koa, e hoʻoneʻe i nā mea kūʻai aku mai nā pale, a laila e hoʻopau i nā'āpana a me nā mea i loaʻaʻole i nā'āpana.

4. Ka hoʻonohonohoʻana o nā'āpana: E nānā i ka PCB Retorked me ka pā hale i paʻiʻia; E hoʻohana i ka hana hoʻonohonoho hoʻonohonoho o ka hoʻonohonohoʻana o ka papa hana hou e koho ai i ka Nozzle kūpono kūpono a hoʻoponopono i ka PCB i kauʻia.

5 Koi pono i ka noʻonoʻo pono e pili ana i nā waiwai a me nā pb hawewe a me nā mea i hoʻohanaʻia, a me nā waiwai o ka mea i hoʻohanaʻia. ʻO ka maʻamau maʻamau ka maʻalahi o ka hana maʻalahi a hoʻohanaʻia no ka hana houʻana i nā'āpana liʻiliʻi.

ʻO ka mīkini kūʻai i alakaʻiʻia

• Kākau i kaʻaoʻao + plc ka hoʻokele pono, maʻalahi a hilinaʻi.

•ʻO ka hoʻolālāʻana mai waho, hoʻolālā kūloko kūloko,ʻaʻole maikaʻi wale nō akā maʻalahi wale nō e mālama.

• Ke hana nei ka Spiray Spirayer i ka atomization maikaʻi me ka hoʻohana haʻahaʻa haʻahaʻa.

•ʻO Turbo Far exhaust me ka pale pale pale e pale ai i ka diffusion o ka flux intomized, e hōʻoia ana i ka hana palekana.

• Loaʻa ka hana hoʻomehana hoʻomehana i ka hoʻomaʻamaʻaʻana no ka mālamaʻana; Hoʻomoe i ka ho'ōlaʻana, ma ka wela wela, ka curve curve, e hoʻoponopono i ka paʻakikī o ke kaʻina hana alakaʻi.

• nā pahu kūʻai aku e hoʻohana ana i ka ikaika kiʻekiʻe,ʻaʻole-deformable thro i ka hao i ka maikaʻi maikaʻi loa.

ʻO nā nozzles i hanaʻia i ka titalnium e hōʻoia i ka hoʻohaʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa a me ka haʻahaʻa haʻahaʻa.

• He hana a ka hoʻomakaʻana o ka hoʻomakaʻana a me ka paniʻana o ka mīkini holoʻokoʻa.